Custom Foam Inserts

We

design and fabricate custom case inserts for hundreds of companies

including all the Government prime contractors as well as the

U.S. Military. We are authorized fabricators/distributors for:

Carpenter Foam Co., Dow Chemical, Foamex, W.T. Burnett, and Zotefoams.

All foam fabrication is done in our 65,000 square foot facility,

which houses the latest equipment including c-n-c routers and

waterjet cutting. We

design and fabricate custom case inserts for hundreds of companies

including all the Government prime contractors as well as the

U.S. Military. We are authorized fabricators/distributors for:

Carpenter Foam Co., Dow Chemical, Foamex, W.T. Burnett, and Zotefoams.

All foam fabrication is done in our 65,000 square foot facility,

which houses the latest equipment including c-n-c routers and

waterjet cutting.

Let one of our Engineers design a case insert for you or use

the following foam selection guideline.

Foam Fabrication Capabilities

Whether it is our design or we are working from your drawing

we have the experience to fabricate your foam insert. We have

the most advanced foam fabrication facility in the Western United

States.

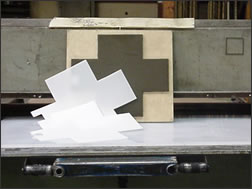

CNC Routing

We can route all polyethylene and closed cell foams including

E.P.S. This process uses a high speed router that follows

AutoCAD drawings to produce complex foam cavities. |

|

| |

|

Die-Cutting

We can die-cut almost all foams. This process uses custom

shaped steel rules that are stamped through the foam. |

|

| |

|

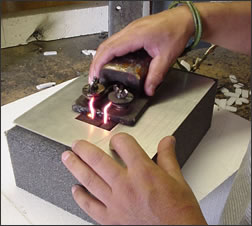

Hot-Wire Cutting

We can hot-wire almost all types of foam. This process

uses custom bent hot wires to produce a wide variety of

complex cavities. |

|

| |

|

Water Jet Cutting

We can water jet cut all types of foam materials. This

process uses pressurized water working @55,000 PSI to cut

through the foam. It follows a computer generated pattern

and can produce complex shapes and cavities very quickly

and efficiently.

|

|

We also have...

- Band saws

- Peelers

- Convoluters

- Laminators

- Hot wire profilers

|

|

Foam

Selection Guide

Use

this handy guide to help you determine your foam needs.

|

|

Foam

Types

We have a foam

to meet any packaging need. |

|

Dow Package Design

Guide

Use this guide

to assist you in the selection and utilization of Dow

Ethafoam polyethylene foam for your protective packaging

application. |

|

|

| |

We Begin With Quality

Quality isn't just in our name. It's

built into our cases from the inside out. We use foam products

from the following top manufacturers: |

| |

|

|

| |

Dow Ethafoam

We are an authorized distributor for Dow Chemical, and carry

the following Ethafoam products: |

| |

|

Ethafoam

220

A a strong, resilient,

medium-density 36 kg/m3 (2.3 pcf), closed-cell

foam. |

|

Ethafoam

220 Anti-Static

Same

as above but with internal anti-static agents. |

|

Ethafoam

HS 45

A strong,

resilient, medium-density (3.9 pcf), closed-cell foam. |

|

Ethafoam

HS 600

A a strong,

resilient, high-density (6.0 pcf), closed-cell foam. |

|

Ethafoam 900

A strong, resilient, high-density

(140 kg/m3), closed-cell foam. |

|

| |

Dow Military

Grade Ethafoam

The Military (M) series of foams listed below are designed

specifically for Military closed case applications. They have

the lowest explosive level of any polyethylene foam available

and they meet stringent military specifications. |

| |

|

Ethafoam

M1

A a strong, resilient,

medium-density 36 kg/m3 (2.3 pcf), closed-cell

foam. |

|

Ethafoam

M1 Anti-Static

Same

as above but with internal anti-static agents. |

|

Ethafoam M3

A strong, resilient, medium-density

(3.9 pcf), closed-cell foam. |

|

Ethafoam M4

A a strong, resilient, high-density

(6.0 pcf), closed-cell foam. |

|

Ethafoam M5

A strong, resilient, high-density

(9.5 pcf), closed-cell foam. |

|

| |

Polyurethane Foam

Check

out the specifications for the two most common polyurethane

foams for case inserts. |

| |

|

| |

| You may require

the free Adobe Acrobat Reader to download and read these

files.

|

|